Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications

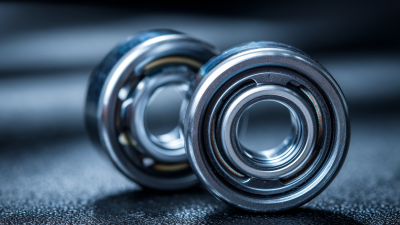

In today's industrial landscape, the demand for high-performance components such as sealed bearings is on the rise, driven by the need for increased efficiency and reliability across various applications. According to a report by Research and Markets, the global ball bearings market is projected to reach $15 billion by 2025, with sealed bearings playing a pivotal role due to their advantages in reducing maintenance costs and extending the lifespan of machinery. As industries from automotive to aerospace increasingly turn to sealed bearings for their superior protection against contaminants and enhanced lubrication retention, choosing the right type has never been more critical.

This ultimate checklist aims to guide engineers and purchasing specialists through the selection process of sealed bearings, ensuring optimal performance and longevity in diverse operational environments.

Key Considerations for Selecting the Perfect Sealed Bearings for Your Project

When selecting the right sealed bearings for your project, several key considerations come into play. First and foremost is the application environment. According to a report by the International Journal of Advanced Manufacturing Technology, approximately 30% of bearing failures can be attributed to contamination from dust and moisture. Therefore, ensuring that the bearings have the appropriate seals to protect against such elements is critical. It’s essential to evaluate the operating conditions, including temperature ranges, load capacities, and potential exposure to chemicals, to choose a bearing that can withstand the specific challenges of your applications.

Another vital aspect to consider is the bearing material. Research indicates that bearings made from high-performance polymers can significantly increase durability and reduce friction in demanding environments. The American Society of Mechanical Engineers (ASME) highlights that using proper materials can enhance the overall lifespan of bearings by up to 50%. When selecting sealed bearings, it's crucial to balance the cost against the potential performance benefits, ensuring that the chosen bearings not only meet your immediate needs but also support long-term reliability and efficiency in your machinery or project.

Understanding Different Types of Sealed Bearings and Their Applications

When it comes to selecting sealed bearings for various applications, understanding the different types and their specific uses is crucial for optimal performance. Sealed bearings, which are designed to keep grease in and contaminants out, can significantly enhance the lifespan and efficiency of machinery. According to a report from Research and Markets, the global market for sealed bearings is projected to reach $75 billion by 2025, highlighting their growing importance across numerous industries, such as automotive, aerospace, and manufacturing.

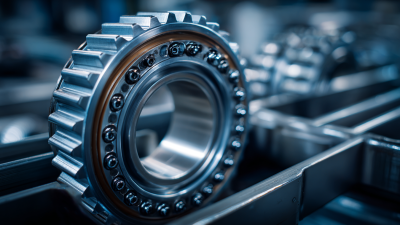

There are several types of sealed bearings, each tailored for specific environments. For instance, deep groove ball bearings are favored in applications requiring high radial loads and moderate axial loads, while angular contact bearings are designed for applications with high-speed and precision requirements. Additionally, specialized sealed bearings developed for extreme conditions, like high temperatures or corrosive environments, can vastly improve operational reliability. The choice of seal material, such as rubber or silicone, also directly influences the bearing's performance and lifespan, demonstrating the critical need for understanding their applications in-depth.

Sealed Bearings Type Comparison

Essential Materials and Coatings for Sealed Bearings Durability

Choosing the right sealed bearings for your applications is crucial for ensuring durability and optimal performance. When considering essential materials for sealed bearings, it's important to prioritize high-quality steel, such as chrome steel or stainless steel, known for their excellent resistance to wear and corrosion. Additionally, advanced polymer materials can also be utilized for their lightweight properties, reducing the overall load on machinery while preventing contamination from external elements.

Choosing the right sealed bearings for your applications is crucial for ensuring durability and optimal performance. When considering essential materials for sealed bearings, it's important to prioritize high-quality steel, such as chrome steel or stainless steel, known for their excellent resistance to wear and corrosion. Additionally, advanced polymer materials can also be utilized for their lightweight properties, reducing the overall load on machinery while preventing contamination from external elements.

Coatings play a pivotal role in enhancing the longevity of sealed bearings. Applying a ceramic or nickel-based coating can provide superior protection against harsh environmental conditions and chemical attack. These coatings can significantly reduce friction and heat generation, resulting in less wear over time.

Tips: Always consider the operating environment of the bearing; if it’s exposed to moisture or corrosive substances, opt for materials that specifically offer enhanced corrosion resistance. Additionally, regular maintenance checks can help identify any issues early, ensuring that your sealed bearings function efficiently throughout their service life.

How to Evaluate the Performance Ratings of Sealed Bearings

When evaluating the performance ratings of sealed bearings, it’s crucial to understand the key metrics that indicate their efficiency and lifespan. Factors such as load ratings, speed ratings, and temperature limits should be carefully assessed to ensure compatibility with your specific applications. According to a report by the International Organization for Standardization (ISO), bearings that meet standardized load ratings can achieve a lifespan of over 20,000 operating hours under optimal conditions.

Tip: Always cross-reference the bearing’s dynamic and static load ratings with your application's requirements. This ensures that the bearings will not only fit but also perform effectively under the expected operating conditions.

Additionally, pay attention to the materials used in manufacturing sealed bearings, as they significantly influence durability and performance. High-quality seals can enhance resistance to contamination, thereby increasing the longevity of the bearings. A study from the American Society of Mechanical Engineers (ASME) revealed that proper sealing techniques can extend bearing lifespan by 30%, making them an essential consideration.

Tip: Evaluate the seal material and design, seeking those rated for your specific environmental conditions, to maximize performance and minimize maintenance.

Common Mistakes to Avoid When Choosing Sealed Bearings

When selecting sealed bearings for your applications, it's crucial to avoid some common pitfalls that can lead to costly downtime and inefficiencies. One major mistake is neglecting to consider the operating environment. According to a report by the International Journal of Engineering Research, around 30% of bearing failures are attributed to environmental factors. Ensure that the chosen sealed bearings are suitable for conditions like moisture, dust, and temperature variations, which can significantly impact performance.

Another frequent oversight is ignoring the application-specific load requirements. The Bearing Specialists Association emphasizes that using bearings beyond their load ratings can lead to premature failure, affecting overall machinery reliability. It is essential to analyze the dynamic and static load conditions carefully to select bearings that meet the specific demands of your application. By addressing these common mistakes, you can enhance the longevity and effectiveness of your sealed bearings, ultimately contributing to smoother operations and reduced maintenance costs.

Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications - Common Mistakes to Avoid When Choosing Sealed Bearings

| Factor | Best Practices | Common Mistakes |

|---|---|---|

| Bearing Type | Choose the type (ball, roller, etc.) based on load requirements. | Choosing a bearing type without analyzing load and speed characteristics. |

| Seal Type | Select seals that provide adequate protection for the environment. | Ignoring environmental conditions when selecting seals. |

| Lubrication | Use the recommended lubricant and consider re-lubrication strategy. | Neglecting lubricant compatibility or using inadequate lubrication. |

| Installation | Follow installation guidelines to prevent damage. | Improper installation leading to premature failure. |

| Load Ratings | Ensure load ratings match application requirements. | Overloading bearings beyond their rated capacity. |

| Temperature Range | Choose bearings designed for specific temperature ranges. | Using bearings outside their temperature threshold. |

| Quality Standards | Select bearings that meet international quality standards. | Forgetting to verify quality certifications. |

Related Posts

-

5 Essential Tips for Choosing the Best Sealed Bearings

-

7 Best Deep Groove Ball Bearings for Unmatched Performance

-

Unlocking the Details of Best Bearing Supplies with Key Technical Parameters for Global Buyers

-

5 Key Factors to Choose the Best Stainless Steel Bearings for Global Procurement

-

Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them

-

Trust in Excellence: Discover the Best Thrust Bearings from China’s Leading Manufacturer