How to Choose the Right Sealed Bearings for Your Industrial Applications

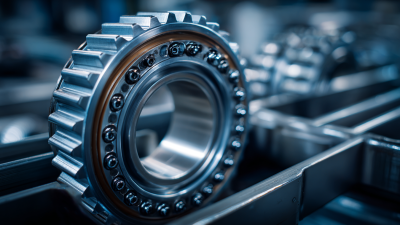

In today's industrial landscape, the selection of the appropriate sealed bearings can significantly influence operational efficiency and equipment longevity. According to recent industry reports, nearly 30% of maintenance costs in manufacturing are attributed to bearing failures, underscoring the critical nature of this decision. Sealed bearings, designed to contain lubricant and exclude contaminants, offer enhanced durability, making them a top choice for a variety of applications.

With advancements in materials and design, using high-quality sealed bearings can reduce friction and wear, leading to improved performance and extended service life. As industries move towards higher productivity targets, understanding the specific needs of your application and the attributes of sealed bearings is essential for minimizing downtime and maximizing return on investment. This guide will provide essential tips for choosing the right sealed bearings tailored to your industrial requirements.

With advancements in materials and design, using high-quality sealed bearings can reduce friction and wear, leading to improved performance and extended service life. As industries move towards higher productivity targets, understanding the specific needs of your application and the attributes of sealed bearings is essential for minimizing downtime and maximizing return on investment. This guide will provide essential tips for choosing the right sealed bearings tailored to your industrial requirements.

Understanding the Different Types of Sealed Bearings for Industrial Use

When selecting sealed bearings for industrial applications, it's essential to understand the various types available and their specific functions. Generally, sealed bearings can be categorized into two main types: rubber-sealed and metal-sealed. Rubber-sealed bearings provide excellent protection against dust and moisture, making them ideal for applications in harsh environments where particle contamination is a concern. The elasticity of rubber allows for a tight seal, ensuring optimal performance while reducing maintenance needs.

On the other hand, metal-sealed bearings offer robust protection and are typically used in applications that involve higher temperatures or heavier loads. The metal seal offers durability and resistance against mechanical wear but may not provide the same level of contamination protection as rubber seals. Additionally, the choice between these two types should also consider the operating speed and lubrication requirements of the application. By evaluating the specific conditions under which the bearings will operate, users can make informed decisions that enhance performance and longevity in their industrial processes.

Sealed Bearings Selection for Industrial Applications

Factors to Consider When Choosing Sealed Bearings for Your Application

When selecting sealed bearings for industrial applications, several key factors should be considered to ensure optimal performance and longevity. First and foremost, the operating environment plays a crucial role. High levels of dust, moisture, or chemical exposure can affect bearing performance, so it’s essential to choose seals that provide adequate protection against these elements. Additionally, understanding the temperature range in which the bearings will operate is vital, as different materials and lubricants may behave differently under varying thermal conditions.

Another critical aspect to take into account is the load and speed ratings of the bearings. Each application has specific requirements pertaining to the weight it must support and the speeds at which it operates. Selecting bearings that match or exceed these specifications ensures reliability and minimizes wear and tear. Finally, maintenance requirements should also influence your choice; some sealed bearings are designed for lifelong lubrication, reducing downtime and maintenance costs in the long run. Careful consideration of these factors will lead to better choices that enhance productivity and reduce total operational costs.

Top Industries that Benefit from Using Sealed Bearings

In today's industrial landscape, the use of sealed bearings has become increasingly prevalent across various sectors, thanks to their efficiency and reliability. Industries such as aerospace, textile, and manufacturing are particularly benefiting from this advanced technology. The aerospace sector relies on sealed bearings for their ability to withstand extreme conditions and reduce maintenance needs, while the textile industry appreciates their durability and low friction, which significantly enhance production efficiency.

Another crucial tip is to assess the maintenance needs of the sealed bearings. Opting for low-maintenance options can save time and reduce costs in the long run, especially for industries with rigorous operational demands. By making informed choices, companies can harness the full potential of sealed bearings, driving efficiency and productivity in their operations.

Maintenance Tips for Extending the Life of Sealed Bearings

When it comes to extending the life of sealed bearings in industrial applications, proper maintenance is crucial. Regular inspection is the first line of defense against premature failure. Operators should frequently check the bearings for any signs of wear, corrosion, or contamination. Keeping the surrounding area clean and free from debris will prevent particles from entering the seals, which could compromise their integrity and performance. Additionally, monitoring the temperature can help detect issues early; operating outside the manufacturer’s recommended temperature ranges can lead to seal degradation.

Lubrication plays a vital role in the longevity of sealed bearings. While these bearings come pre-lubricated, it's important to follow the manufacturer’s guidelines on re-lubrication intervals. Using the correct type of lubricant and ensuring that it is applied in the right amount can significantly affect bearing performance and lifespan. Over-lubrication can lead to increased pressure inside the bearing, causing seals to fail, while under-lubrication might result in insufficient protection against friction and wear.

By adhering to these maintenance tips, industrial operators can optimize the performance of their sealed bearings and enhance the overall efficiency of their equipment.

Common Mistakes to Avoid When Selecting Sealed Bearings

When selecting sealed bearings for industrial applications, avoiding common pitfalls is essential for ensuring optimal performance and longevity. One major mistake is neglecting the importance of equipment condition monitoring. The reliability of seals heavily depends on how well plant personnel keep an eye on the equipment's state and analyze any failures systematically. Implementing a robust monitoring system can significantly enhance the understanding of seal performance, ultimately leading to better selection and maintenance practices.

Another frequent error is failing to consider the mean time between failures (MTBF) for seals. Accurately calculating MTBF rests on a clear definition of what constitutes a failure. Misinterpretations can lead to underestimating the reliability of bearings and making incorrect choices that could compromise operational efficiency. Furthermore, as technology evolves, it’s vital to stay updated with the latest innovations in hub and wheel end systems. Modern designs not only offer increased maintainability but also simplify complex applications, making it easier to select the right sealed bearings that align with both operational needs and technological advancements.

How to Choose the Right Sealed Bearings for Your Industrial Applications - Common Mistakes to Avoid When Selecting Sealed Bearings

| Application | Bearing Type | Common Mistakes | Recommended Features | Maintenance Frequency |

|---|---|---|---|---|

| Conveyor Systems | Deep Groove Ball Bearings | Overlooking load capacity | Seal type suitable for dust | Quarterly |

| Electric Motors | Angular Contact Bearings | Ignoring speed ratings | High-speed lubrication | Monthly |

| Pumps | Self-Aligning Ball Bearings | Choosing wrong sealing material | Corrosion-resistant seals | Bi-annual |

| Automotive Applications | Tapered Roller Bearings | Neglecting alignment issues | Angular contact design for load | Yearly |

| Industrial Machinery | Spherical Roller Bearings | Underestimating temperature range | High temperature withstand | Monthly |

Related Posts

-

5 Essential Tips for Choosing the Best Sealed Bearings

-

Ultimate Checklist for Choosing the Right Sealed Bearings for Your Applications

-

Trust in Excellence: Discover the Best Thrust Bearings from China’s Leading Manufacturer

-

The Evolution of Best Miniature Bearings in Advanced Technologies

-

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

-

Future Trends in Self Aligning Bearing Technology for 2025 and How to Leverage Them