How to Choose the Right Small Ball Bearings for Your Project Needs

When embarking on a new engineering project, selecting the right small ball bearings is crucial for ensuring operational efficiency and longevity of the machinery. According to a report by the Global Ball Bearings Market Outlook 2023, the small ball bearings segment is expected to grow at a CAGR of 4.5% over the next five years, largely driven by advancements in automation and increasing demand in various industries such as automotive, aerospace, and medical devices. As the backbone of many applications, these components require careful consideration in terms of dimensions, load ratings, and material characteristics to meet specific application needs.

Industry expert Dr. Emily Chen, a leading figure in bearing technology, emphasizes the importance of proper selection: "The performance reliability of small ball bearings can significantly influence the efficiency of an entire system." This sentiment resonates deeply in a landscape where precision and performance are paramount. Whether you are developing a compact motor or a high-precision instrument, understanding the selection criteria for small ball bearings will not only enhance your product's performance but also optimize its cost-effectiveness in the long run. Therefore, it is essential to explore the various factors that make small ball bearings suitable for your specific project requirements.

Understanding the Basics of Small Ball Bearings

Small ball bearings are essential components in a wide variety of mechanical applications, providing support and allowing for smooth rotational movement. Understanding their basic structure and function is crucial for selecting the right bearings for your project. Typically made from high-quality steel or ceramic materials, small ball bearings consist of inner and outer races that house the balls within. The balls reduce friction between the moving parts, facilitating efficient operation and enhancing the lifespan of the machinery.

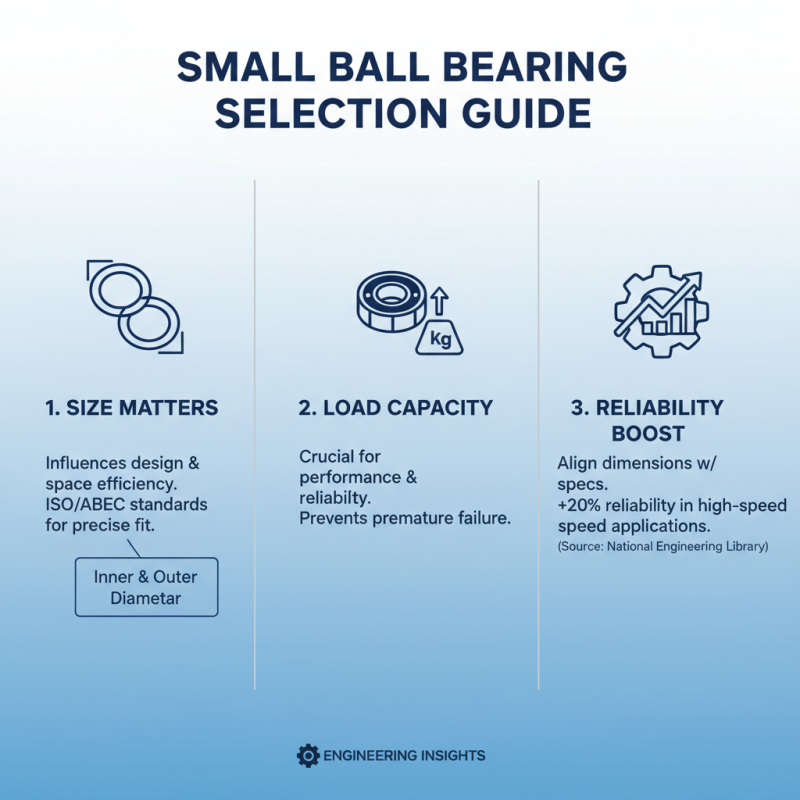

When considering small ball bearings, it's important to recognize their specifications, such as size, load capacity, and operational speed. The inner diameter, outer diameter, and width determine compatibility with your application, while the load rating helps ensure that the bearings can withstand the forces they will encounter. Additionally, factors like lubrication and sealing options play a significant role in the performance and maintenance of the bearings. Proper selection based on these fundamental aspects can lead to significant improvements in efficiency and functionality for any project.

How to Choose the Right Small Ball Bearings for Your Project Needs - Understanding the Basics of Small Ball Bearings

| Bearing Type | Dimensions (mm) | Load Capacity (N) | Material | Applications |

|---|---|---|---|---|

| Miniature Ball Bearing | 6 x 12 x 4 | 100 | Stainless Steel | Robotics, RC Vehicles |

| Small Deep Groove Bearing | 8 x 22 x 7 | 200 | Chrome Steel | Electric Motors, Machine Tools |

| Instrument Bearing | 10 x 30 x 9 | 300 | Plastic | Instrumentation, Precision Equipment |

| Ceramic Ball Bearing | 12 x 28 x 8 | 350 | Ceramic | High-Speed Applications |

| Standard Ball Bearing | 12 x 32 x 10 | 400 | Carbon Steel | General Machinery |

Identifying Project Requirements for Bearing Selection

When selecting small ball bearings for your project, it’s crucial to start with a clear understanding of your project requirements. Consider the operating environment where the bearings will be used — factors such as temperature, humidity, and exposure to contaminants can significantly impact bearing performance. For instance, if the bearings will be exposed to moisture, you might need to consider options with corrosion-resistant materials or seals.

Tips: Always evaluate the load requirements of your application. Understanding whether your project will experience dynamic or static loads can determine the type of bearing needed. If your application involves high-speed rotations, ensure that the bearings you choose can handle the resulting centrifugal forces without compromising their lifespan.

Another key aspect is the noise and vibration tolerance of the bearings. Depending on your project, particularly in applications like small motors or electronics, minimizing noise could be essential. Assess the required precision and tolerance levels to ensure that the ball bearings can perform optimally without introducing excessive vibrations that might affect overall functionality.

Tips: Before finalizing your selection, consult with manufacturers or technical experts who can offer insights based on the specific requirements of your application. Don’t hesitate to ask for samples to test in your project — this can help identify any unforeseen issues before full-scale production.

Exploring Different Types of Small Ball Bearings

When selecting small ball bearings for various engineering and manufacturing projects, it's essential to understand the different types available and their specific applications. Generally, small ball bearings can be categorized into radial bearings, thrust bearings, and angular contact bearings. Radial bearings are designed to support loads perpendicular to the shaft, making them ideal for applications like electric motors and machinery. According to a recent market analysis, the global small ball bearing market is expected to grow at a CAGR of 7.8% over the next five years, driven by the demand in automotive and industrial machinery sectors.

Thrust bearings, on the other hand, support loads parallel to the axis of rotation and are commonly used in applications where axial loads are prevalent, such as in gearboxes and conveyor systems. The demand for thrust ball bearings is on the rise, particularly in high-performance environments, where they provide a compact solution that could contribute to weight and space savings. Moreover, angular contact bearings are designed to handle both radial and axial loads simultaneously, making them a versatile choice for complex machinery. According to industry reports, the growing trend toward automation in manufacturing is further propelling the need for bearings that can withstand higher operational speeds and loads, pushing designers to consider advanced materials and lubricants in their selection processes.

Small Ball Bearings Selection Criteria

This chart illustrates the different characteristics of small ball bearings that you need to consider for your project. The data shows the relative importance of factors like material, load capacity, speed, and precision when selecting the appropriate ball bearing.

Evaluating Material Options and Their Impact on Performance

When choosing small ball bearings for a project, evaluating material options is crucial as it significantly impacts performance. Different materials, such as stainless steel, ceramic, and plastic, have unique properties that make them suitable for specific applications. According to a report by the International Society for Bearings Research, stainless steel bearings are favored in environments where corrosion resistance is vital, while ceramic bearings are known for their lightweight and high-speed capabilities. Plastic bearings offer a cost-effective solution for non-load-bearing applications and can be self-lubricating, reducing the need for maintenance.

Tip: Consider the operating environment when selecting materials. For instance, if your project involves exposure to moisture or chemicals, stainless steel or specially coated materials would provide enhanced durability against corrosion. Conversely, for applications with high speeds and low friction, ceramic bearings may yield better performance over time.

Another important aspect to consider is the bearing's operational temperature range. Materials react differently under varying temperatures, which can affect performance and lifespan. A study published in the Journal of Tribology indicates that while metals may lose strength at high temperatures, ceramics maintain their integrity better, making them ideal for high-temperature applications.

Tip: Always refer to the manufacturer's specifications for temperature ratings and ensure that your chosen material aligns with the expected conditions to avoid premature failure. Balancing the material properties with your project requirements will lead to optimal performance and reliability.

Assessing Size and Load Capacity for Your Specific Application

When selecting small ball bearings for your project, assessing the size and load capacity is crucial. The bearing size influences the overall design, as it impacts space efficiency and performance. For example, the ISO/ABEC standards provide specific dimensions for inner and outer diameters, which helps engineers to select bearings that fit seamlessly into their assemblies. According to the National Engineering-Library, ensuring that the bearing dimensions align with the design specifications can enhance reliability by up to 20% in high-speed applications.

Load capacity is another critical factor to consider. It refers to the maximum load a bearing can support while maintaining performance and durability. This is usually categorized into dynamic and static load ratings, with the former being essential for rotating applications. According to the American Bearing Manufacturers Association (ABMA), understanding these ratings is vital for minimizing the risk of premature failure. For instance, a bearing that operates under a dynamic load below its rated capacity can last significantly longer—up to five times in some cases—compared to one that operates close to its limit. Evaluating the specific loads your application will impose will guide you toward selecting the optimal bearing size and type, ensuring an efficient and reliable outcome in your project.

Related Posts

-

How to Choose the Right Small Ball Bearings for Your Project

-

Top Benefits of Using Small Ball Bearings in Various Applications

-

How to Choose the Right Ball Bearing Rollers for Your Application Needs

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

What are the Key Benefits of Using Steel Ball Bearings in Modern Machinery?

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair