How to Efficiently Use the Best Ball Bearing Puller for Optimal Results

In the ever-evolving landscape of industrial technology, the effective use of tools is paramount for enhancing productivity and achieving optimal results. Among these essential tools is the ball bearing puller, a device that enables users to safely and efficiently remove bearings from various machinery without causing damage. As industries strive for efficiency and precision in their operations, understanding the latest technological trends and methodologies surrounding the use of a ball bearing puller becomes crucial.

This blog will explore best practices, innovative techniques, and a comprehensive checklist designed to empower professionals in 2025 and beyond. By mastering the use of the ball bearing puller, technicians can not only improve their workflow but also contribute to the overall success and sustainability of their enterprises.

This blog will explore best practices, innovative techniques, and a comprehensive checklist designed to empower professionals in 2025 and beyond. By mastering the use of the ball bearing puller, technicians can not only improve their workflow but also contribute to the overall success and sustainability of their enterprises.

Common Mistakes to Avoid When Using Ball Bearing Pullers

When using a ball bearing puller, it's crucial to avoid common mistakes to ensure optimal results and efficiency. One frequent error is applying excessive force without proper alignment. This often leads to damage not only to the bearing but also to the components surrounding it. To prevent this, always double-check that the puller jaws are perfectly positioned around the bearing. A well-aligned puller will significantly reduce the risk of slippage or breakage during the extraction process.

Another mistake is neglecting the importance of lubrication. Some users overlook this step, thinking that a dry puller will suffice. However, applying a suitable lubricant can facilitate a smoother and more controlled removal, minimizing wear on both the puller and the bearing. Furthermore, be cautious about the type of lubricant used; certain products might react adversely with some materials, leading to further complications. By prioritizing proper alignment and lubrication, you can effectively enhance the performance of your ball bearing puller and achieve smoother operations.

Essential Features to Look for in a High-Quality Ball Bearing Puller

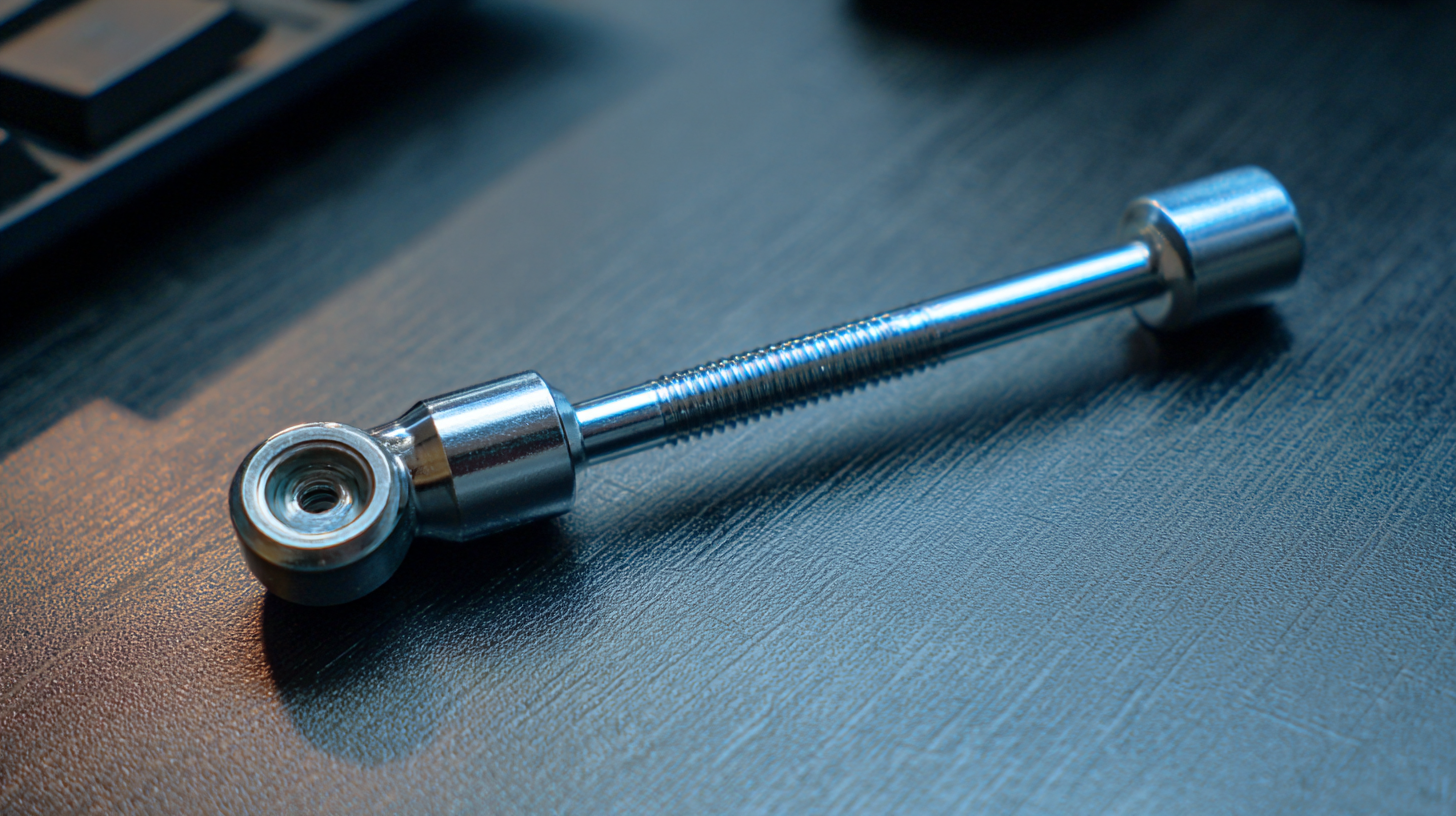

When selecting a high-quality ball bearing puller, several essential features should guide your decision. Firstly, ensure that the puller is made from robust materials such as high-carbon steel, which increases durability and performance during repeated use. A good puller should also have a corrosion-resistant finish, helping to maintain its integrity even in tough conditions.

Another crucial aspect is the design of the tool. Look for a puller with a versatile jaw configuration that can accommodate different sizes and types of bearings. This flexibility not only makes the tool more efficient but also saves money by reducing the need for multiple pullers. Additionally, a puller with a built-in locking mechanism enhances safety and control during operation.

Tips for efficient use include always preparing the bearing and shaft surfaces by cleaning them to avoid damage. Furthermore, applying heat to the outer housing can expand it slightly, making the bearing easier to remove. Lastly, when using the puller, ensure that the tension is evenly distributed by adjusting the center bolt gradually, which will provide better leverage and prevent damage.

Step-by-Step Guide to Properly Using a Ball Bearing Puller

When it comes to efficiently using a ball bearing puller, understanding the step-by-step process is key to achieving optimal results. Begin by ensuring that you have the right equipment on hand—not just the ball bearing puller itself, but also any necessary safety gear, such as gloves and eye protection. Before you start the removal process, clean the surrounding area to make sure there's no debris that could interfere with your work.

Next, carefully position the puller over the bearing, ensuring it is aligned correctly. Tighten the puller’s arms securely around the bearing to prevent slippage during the extraction. Gradually apply pressure using the puller’s screw mechanism, observing how the bearing begins to loosen. Patience is crucial here; rushed actions may damage the bearing or the surrounding components. By following this systematic approach, you can efficiently remove ball bearings with precision, minimizing the risk of error and ensuring that your project proceeds smoothly.

Ball Bearing Puller Efficiency Analysis

Maintenance Tips to Extend the Life of Your Ball Bearing Puller

To maximize the lifespan of your ball bearing puller, regular maintenance is vital. Just as manufacturers emphasize the importance of upkeep for equipment like sweeper tires, a proactive approach can significantly enhance the performance and longevity of your puller. Regular inspections are essential; check for wear and tear on the jaws and pivot points. Keeping moving parts lubricated reduces friction, which can lead to premature failure—data from industry reports show that machines properly lubricated can experience a lifespan increase of up to 30%.

Operator behavior also plays a crucial role in extending the life of your ball bearing puller. Following manufacturer guidelines for load specification and usage can prevent undue stress on the tool. For instance, improper use accounts for nearly 70% of mechanical failures, reflecting the critical nature of operator awareness and adherence to best practices. Additionally, storing your tool in a clean, dry environment prevents rust and corrosion, further contributing to its longevity.

By implementing these maintenance tips and ensuring responsible usage, you can achieve optimal performance from your ball bearing puller, much like the recommendations given for other equipment in the industry.

Troubleshooting Common Problems During the Pulling Process

When it comes to using a ball bearing puller, troubleshooting common problems during the pulling process can significantly enhance efficiency and ensure optimal results. One prevalent issue is the puller slipping off the bearing. To prevent this, ensure that the attachments are properly secured to the bearing, and consider using a strap wrench for added grip. A clean work surface also plays a vital role—debris can cause misalignment, leading to further complications.

Another common challenge is difficulty in applying enough force to extract the bearing. In such cases, lubricating the shaft can reduce friction, making it easier to pull the bearing free. Additionally, applying force gradually can help prevent sudden impacts that could damage the components. Lastly, always monitor your tools for wear and tear—damaged pullers can exacerbate problems. By keeping these tips in mind, you can troubleshoot and resolve issues effectively during the pulling process.