What is a geomembrane welding machine and how does it work?

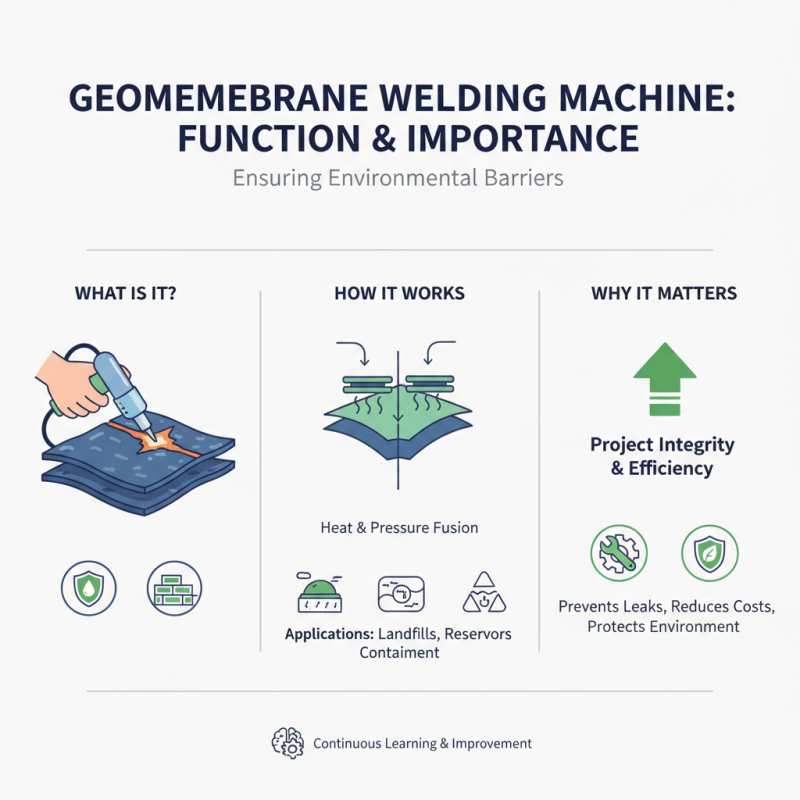

In the world of industrial applications, understanding the role of a geomembrane welding machine is essential. Dr. Emily Chen, a renowned expert in environmental engineering, notes, "The efficiency of geomembrane welding machines can significantly impact project timelines and integrity." These machines are crucial in constructing barriers for waste containment, water reservoirs, and landfills.

A geomembrane welding machine uses heat or pressure to join layers of geomembrane materials. This process ensures waterproof seals. Each weld needs precision and skill. However, not all machines perform equally. Operators must be trained to avoid common pitfalls. Failure to achieve proper bond strength could lead to leaks and costly repairs.

The technology behind geomembrane welding continues to evolve. Yet, challenges remain. Factors like weather and material type can complicate the welding process. It’s important to keep learning and improving practices within this field. A better understanding of geomembrane welding machines improves both quality and safety in construction projects.

What is a Geomembrane Welding Machine?

A geomembrane welding machine is essential in construction and environmental applications. It is used to join sheets of geomembrane materials, which are crucial in lining landfills, ponds, and reservoirs. These machines operate mainly through heat fusion, ensuring a strong bond that prevents leakage and contamination. According to industry reports, the global geomembrane market is expected to reach $4 billion by 2027, underscoring the importance of reliable welding technology.

The welding process typically involves applying heat and pressure to the edges of two geomembranes. This melts the material, creating a solid joint upon cooling. The effectiveness of this welding significantly impacts the integrity of containment systems. A study noted that improper welding techniques can result in failure rates of up to 20%. Therefore, skilled operators and proper training are crucial.

In practice, challenges do arise. Environmental factors, like temperature fluctuations, can affect welding quality. Even minor imperfections in the seams can lead to serious long-term issues. Regular maintenance of welding machines is vital, as wear and tear can compromise performance. Operators must be vigilant and proactive about their equipment's condition. Only then can they ensure optimal results and enhance the lifespan of geomembrane projects.

Key Components of Geomembrane Welding Machines

Geomembrane welding machines are essential in the construction and environmental industries. They join geomembranes, which are crucial for waterproofing. These machines ensure that seams are strong and durable. A few key components define how they work.

The heating element is vital. It uses controlled heat to fuse geomembranes. Quality control here is crucial. If the temperature is off, the seams could fail. Another important component is the pressure roller. It applies necessary pressure while welding. Without this, the weld may not bond properly. Lastly, the control system regulates the machine’s functions. It monitors temperature, speed, and pressure. Users often find this complex.

Operators must be trained. Missteps during operation can lead to issues. Regular maintenance is essential too. Wear and tear can affect performance. Understanding these components helps improve the welding process. Geomembrane welding machines are not perfect. They require constant evaluation and adjustment.

How Geomembrane Welding Machines Operate

Geomembrane welding machines are crucial in creating secure and durable seals for geomembranes. These machines use heat, electric currents, or radio frequency to bond materials. They ensure the integrity of barriers used in landfills and reservoirs.

When these machines operate, they preheat the geomembrane edges. The process uses various welding techniques, such as hot air welding and wedge welding. According to industry reports, effective welding can achieve over 90% bond strength in geomembranes. This is vital for landfills, where leaks may lead to severe environmental damage.

Despite advancements, challenges remain. Variable material thickness can affect the quality of welds. Operational inconsistencies can lead to compromised seams. Regular training and maintenance are often overlooked. Industry standards recommend frequent inspections, yet compliance varies widely. Addressing these gaps could enhance performance in the field.

What is a geomembrane welding machine and how does it work? - How Geomembrane Welding Machines Operate

| Feature | Description |

|---|---|

| Type of Welding | Hot air welding, extrusion welding, and ultrasonic welding. |

| Common Applications | Landfills, ponds, reservoirs, and mining applications. |

| Material Compatibility | HDPE, LLDPE, PVC, and polypropylene geomembranes. |

| Power Source | Electric powered, gas powered, or battery operated options available. |

| Welding Speed | Typically ranges from 2 to 10 meters per minute depending on the machine type. |

| Temperature Control | Integrated thermostats to monitor and regulate welding temperature. |

| Operator Training | Specialized training is recommended for safe and effective operation. |

| Maintenance | Regular cleaning and inspection to ensure optimal performance. |

Different Welding Techniques Used in Geomembrane Machines

Geomembrane welding machines play a vital role in various industries. They are used to create watertight seals in materials. Different welding techniques are employed in these machines. Each technique has its unique advantages and applications.

The hot wedge welding method is popular for its speed and efficiency. It uses a heated wedge to melt the seams of geomembrane materials. This method is effective for thick membranes and offers strong bonding. [Image Placeholder]

Then, there is the double welding technique, which emphasizes reliability. It involves two seams being welded simultaneously, providing redundancy in case of failure. This adds an extra layer of security, especially in critical applications.

However, not all techniques are perfect in every scenario. The quality of the welding can vary based on temperature settings or material types. Sometimes, improper technique leads to weak seals, which can be a significant issue. Fine-tuning these processes requires careful consideration and skill. Understanding these welding techniques is crucial for maximizing performance in geomembrane applications.

Applications and Benefits of Geomembrane Welding Technology

Geomembrane welding technology plays a crucial role in many industries. It provides effective solutions for containment issues, especially in waste management and water conservation. These machines use heat and pressure to join geomembrane sheets seamlessly. This method ensures strong, reliable barriers for liquids and gases.

Applications of geomembrane welding extend to landfills, mining, and agricultural ponds. In landfills, they prevent leachate from contaminating groundwater. For mining, they contain hazardous materials efficiently. Agricultural ponds benefit by retaining water, reducing evaporation rates. Each application showcases how geomembrane welding technology addresses specific challenges.

The benefits of this technology are significant. It enhances environmental protection by minimizing leakage risks. It also saves time and labor compared to traditional methods. However, not all projects may experience the same success. Some welds may weaken or fail if not executed properly. It’s essential to conduct regular inspections and maintenance. This technology is promising, yet requires careful handling to ensure proper functionality.