What are the Key Benefits of Using Steel Ball Bearings in Modern Machinery?

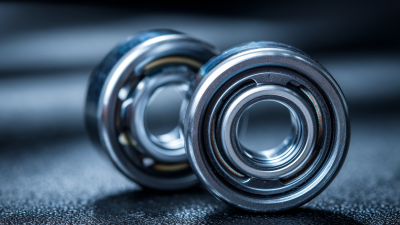

In the realm of modern machinery, the importance of precision and reliability cannot be overstated. One crucial component that significantly enhances these characteristics is steel ball bearings. These small yet powerful elements play a vital role in reducing friction and ensuring smooth motion in various mechanical systems. As industries continuously strive for improved efficiency and performance, steel ball bearings have emerged as a preferred choice for engineers and manufacturers alike. Their robust construction not only contributes to longevity and durability but also allows for optimal load distribution, making them essential in applications ranging from automotive to aerospace.

This blog aims to explore the key benefits of using steel ball bearings in modern machinery, shedding light on why they are indispensable in today’s fast-paced industrial landscape.

Understanding the Role of Steel Ball Bearings in Enhancing Machine Performance

Steel ball bearings are critical components in modern machinery, playing a vital role in enhancing performance and efficiency. Their unique design allows for smooth rotational movement, reducing friction and wear between moving parts. According to a report from the American Society of Mechanical Engineers, the use of high-quality steel ball bearings can decrease energy consumption in machinery by up to 30%, which is especially significant in large-scale manufacturing and industrial applications where energy efficiency directly impacts operational costs.

Steel ball bearings are critical components in modern machinery, playing a vital role in enhancing performance and efficiency. Their unique design allows for smooth rotational movement, reducing friction and wear between moving parts. According to a report from the American Society of Mechanical Engineers, the use of high-quality steel ball bearings can decrease energy consumption in machinery by up to 30%, which is especially significant in large-scale manufacturing and industrial applications where energy efficiency directly impacts operational costs.

Moreover, steel ball bearings contribute to the longevity and reliability of machinery. Research indicates that machinery utilizing premium steel bearings can experience a 50% reduction in maintenance downtime due to their durability. This longevity not only saves costs associated with repairs and replacements but also helps maintain consistent productivity levels. Different industries, such as automotive and aerospace manufacturing, heavily rely on these efficiencies, illustrating the critical role of steel ball bearings in sustaining high-performance machinery under demanding conditions. As technology advances, innovations in bearing design and materials continue to enhance their effectiveness, ensuring they remain indispensable for modern machinery.

Examining the Durability and Longevity of Steel Ball Bearings in Industrial Applications

Steel ball bearings are essential components in modern machinery, providing numerous benefits that enhance performance and efficiency. Their durability and longevity make them particularly advantageous for industrial applications. Given the rigorous demands placed on machinery in sectors such as manufacturing and automotive, the ability of steel ball bearings to withstand significant wear and tear under heavy loads is crucial. The mechanical properties of steel allow these bearings to maintain their structural integrity over time, promoting consistent operation and reducing the need for frequent replacements.

Steel ball bearings are essential components in modern machinery, providing numerous benefits that enhance performance and efficiency. Their durability and longevity make them particularly advantageous for industrial applications. Given the rigorous demands placed on machinery in sectors such as manufacturing and automotive, the ability of steel ball bearings to withstand significant wear and tear under heavy loads is crucial. The mechanical properties of steel allow these bearings to maintain their structural integrity over time, promoting consistent operation and reducing the need for frequent replacements.

Recent studies into materials such as grey cast iron with copper additions indicate a growing interest in optimizing performance through innovative material combinations. While the focus may be on valve guides in internal combustion engines, the insights gained can be applied to improve bearing designs as well. By examining the microstructural and wear characteristics of these materials, engineers can develop steel ball bearings that not only endure harsh conditions but also enhance the overall efficiency of machinery. This synergy between advanced materials and traditional bearing technology promises to drive further innovations in industrial applications.

Comparing Steel Ball Bearings with Other Bearing Materials for Optimal Efficiency

When it comes to modern machinery, the choice of bearing materials significantly affects operational efficiency and durability. Steel ball bearings stand out for their superior performance when compared to alternatives such as plastic, ceramic, or bronze materials. One of the main advantages of steel ball bearings is their ability to withstand higher loads and resist wear, thanks to their robust structure. This makes them particularly suitable for applications requiring precision and reliability, like in automotive or aerospace industries where safety and efficiency are paramount.

Additionally, steel ball bearings offer enhanced thermal conductivity, which aids in heat dissipation during high-speed operations. Unlike plastic bearings, which can warp under extreme temperatures, steel maintains its shape, ensuring consistent performance. Comparatively, ceramic bearings, while lightweight and resistant to corrosion, can be more brittle, making them less ideal for dynamic environments where shock loading is prevalent. By choosing steel ball bearings, manufacturers can achieve an optimal balance of cost-effectiveness and excellence in mechanical performance, making them a preferred choice in modern machinery design.

What are the Key Benefits of Using Steel Ball Bearings in Modern Machinery? - Comparing Steel Ball Bearings with Other Bearing Materials for Optimal Efficiency

| Bearing Material | Load Capacity (N) | Speed Limit (RPM) | Operating Temperature (°C) | Corrosion Resistance | Cost (per unit) |

|---|---|---|---|---|---|

| Steel Ball Bearings | 5000 | 3000 | 150 | Moderate | $1.50 |

| Ceramic Ball Bearings | 3000 | 5000 | 200 | High | $5.00 |

| Plastic Ball Bearings | 2000 | 2000 | 80 | Excellent | $0.75 |

| Stainless Steel Ball Bearings | 4500 | 2500 | 120 | Very High | $2.50 |

Exploring the Cost-Effectiveness of Using Steel Ball Bearings in Modern Machinery

The cost-effectiveness of using steel ball bearings in modern machinery cannot be overstated. Steel ball bearings are known for their durability and low maintenance requirements, making them a wise investment for manufacturers. They reduce friction and wear in moving parts, which extends the lifespan of machinery and decreases the need for frequent replacements. This longevity can lead to significant cost savings over time, especially in high-demand industrial environments.

Tip: When selecting steel ball bearings, consider the specific load and speed requirements of your machinery. Using bearings that are optimized for your application can enhance performance and reduce energy costs.

Moreover, steel ball bearings are widely available and relatively inexpensive compared to other materials. The economies of scale in their production mean that manufacturers can source quality bearings without breaking the bank. This affordability enables businesses to allocate resources more efficiently and invest in other critical areas of operations, ultimately fostering growth and innovation.

Tip: Always compare different suppliers and materials when procuring ball bearings. Look for suppliers who offer bulk discounts or loyalty programs to maximize your savings.

Evaluating the Impact of Steel Ball Bearings on Reducing Friction and Wear in Machines

Steel ball bearings are crucial components in modern machinery, and their impact on reducing friction and wear cannot be overstated. According to a report from the National Lubricating Grease Institute, utilizing high-quality steel ball bearings can lead to a friction reduction of up to 50% compared to traditional bearing materials. This significant reduction not only enhances the efficiency of machinery but also prolongs the lifespan of moving parts, ultimately saving on maintenance and replacement costs.

Moreover, studies indicate that proper lubrication combined with steel ball bearings can further minimize wear rates. The operating temperatures can be reduced by as much as 15% when using advanced lubricants designed for use with steel ball bearings. This temperature reduction directly correlates to lower wear and tear, affirming the value of investing in quality bearings for performance-driven applications.

**Tip:** Regularly inspect and maintain your ball bearings, ensuring they are properly lubricated to maximize their lifespan and performance. Consider using synthetic lubricants for better heat resistance and lower friction.

**Tip:** When selecting bearings, opt for those with high tolerance ratings, as they can significantly reduce misalignment issues and improve overall machinery efficiency.

Impact of Steel Ball Bearings on Reducing Friction and Wear in Modern Machinery

Related Posts

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

-

7 Best Deep Groove Ball Bearings for Unmatched Performance

-

What Makes Ceramic Balls Essential for Modern Manufacturing

-

7 Reasons Why Deep Groove Ball Bearings are Essential for Your Business Success

-

5 Reasons Why Ceramic Bearings Are the Best Choice for High-Performance Applications