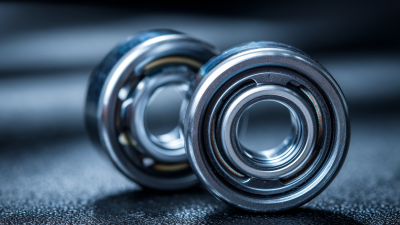

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

In the realm of modern engineering and manufacturing, the choice between stainless steel ball bearings and plastic bearings has become increasingly critical for optimizing performance and durability. According to a report by the International Bearing Association, stainless steel ball bearings account for approximately 70% of the global bearing market, attributed to their superior load capacity and resistance to corrosion. In contrast, plastic bearings, which are rising in popularity due to their lightweight and low-friction advantages, represent a growing segment valued for their application in environments where lubrication is challenging.

This blog aims to deliver a comprehensive performance comparison, exploring key aspects such as wear resistance, operating temperature ranges, and cost-effectiveness, thereby equipping industry professionals with essential tips for selecting the most suitable bearing type for their specific applications.

Stainless Steel Bearings: Advantages and Key Applications

The increasing demand for lightweight helicopters is influencing the growth of the bearing market, particularly in sectors such as emergency medical services and commercial aviation. As reported in various industry analyses, the global helicopter market is expected to see a compound annual growth rate (CAGR) of approximately 4.5% over the next five years, driven by the need for agile and efficient aerial solutions. This surge is notably increasing the focus on reliable and high-performance components, including bearings.

Stainless steel ball bearings stand out in this context due to their inherent mechanical strengths and longevity. They offer advantages such as higher load capacity, enhanced corrosion resistance, and improved operational stability, making them ideal for the rigorous demands of aviation applications. In fact, studies indicate that stainless steel bearings can outperform their plastic counterparts by up to 30% in load-bearing situations, substantially contributing to the safety and efficiency of lightweight helicopters. As these machines become more prevalent in both commercial and military sectors, the demand for such durable bearings is likely to experience a parallel rise, ensuring operational reliability in critical missions.

Plastic Bearings: Benefits and Use Cases in Various Industries

Plastic bearings have gained significant traction across various industries due to their unique advantages, some of which are well-documented in industry reports. Unlike traditional stainless steel ball bearings, plastic bearings boast exceptional resistance to corrosion, making them ideal for use in environments exposed to moisture and chemicals. According to a report by the American Society for Testing and Materials (ASTM), plastic bearings can last up to five times longer than metal counterparts when used in corrosive conditions, significantly reducing maintenance costs.

In high-load applications, such as in the automotive and aerospace industries, the lightweight nature of plastic bearings contributes to overall system efficiency. A study by the Society of Automotive Engineers (SAE) highlighted that the use of plastic bearings in automotive components led to a 15% reduction in weight, which consequently improved fuel efficiency. Furthermore, plastic bearings provide excellent performance in the food and beverage sector due to their ability to operate without lubricant, complying with stringent hygiene regulations. The Food and Drug Administration (FDA) indicates that bearings made from FDA-compliant plastics are increasingly being utilized in food processing equipment, ensuring safety and reliability.

Performance Comparison: Speed, Load Capacity, and Durability

When comparing stainless steel ball bearings and plastic bearings, several performance attributes must be considered, including speed, load capacity, and durability. Stainless steel bearings typically exhibit superior speed performance, capable of handling higher RPMs without compromising structural integrity. According to the International Organization for Standardization (ISO), stainless steel bearings can operate efficiently at speeds exceeding 30,000 RPM, while plastic bearings generally peak around 15,000 RPM, making them less suitable for high-speed applications.

In terms of load capacity, stainless steel bearings usually outperform their plastic counterparts. They can sustain heavier loads due to their robust material properties; industry reports indicate that stainless steel bearings have a dynamic load rating often exceeding 5,000 N. Plastic bearings, while lighter and resistant to corrosion, typically offer a dynamic load rating closer to 1,000 N, limiting their application in heavy-duty scenarios.

Tips: When selecting bearings for your application, consider the environment and expected load. For high-speed, high-load applications, stainless steel is the go-to option. Conversely, for lighter loads and corrosion-prone environments, explore high-performance plastic bearings. Remember to consult manufacturer specifications to ensure optimal performance and longevity for your project.

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

This chart compares the performance parameters of stainless steel ball bearings with plastic bearings, focusing on speed, load capacity, and durability.

Cost Analysis: Short-term vs. Long-term Investment in Bearings

When comparing stainless steel ball bearings and plastic bearings, the cost analysis between short-term and long-term investment is crucial. While stainless steel bearings often have a higher upfront cost due to their durability and performance, they typically offer lower maintenance costs and a longer lifespan. Studies indicate that stainless steel bearings can have a lifecycle up to seven times longer than that of plastic bearings, which can wear down more quickly under high loads or harsh environments.

In the realm of investing, understanding the return on invested capital (ROIC) is essential for evaluating the true value produced by any material choice. For instance, investing in stainless steel bearings, although more expensive initially, can yield a higher ROIC when factoring in reduced operational disruptions and replacement costs over time. Conversely, plastic bearings may appear more cost-effective at first glance but could lead to higher long-term expenditures due to frequent replacements and maintenance challenges. Thus, for organizations seeking to optimize their resource allocation, a detailed cost-benefit analysis considering both upfront and ongoing expenses is critical in making an informed decision that aligns with broader financial strategies.

Environmental Impact: Sustainability of Stainless Steel vs. Plastic Bearings

When comparing stainless steel ball bearings to plastic bearings, one of the critical considerations is the environmental impact of materials used in their production. Stainless steel is a durable, long-lasting option that can withstand extreme conditions, which often means less frequent replacements and lower overall waste. Moreover, stainless steel is fully recyclable, and its production processes have improved over the years to reduce carbon footprints. This makes it a more sustainable choice in applications where longevity and performance are prioritized.

On the other hand, plastic bearings, while often lighter and more resistant to corrosion, can pose environmental challenges. Many plastics are derived from fossil fuels, and the production and disposal processes can lead to significant environmental degradation. However, the emergence of biodegradable plastics offers a glimmer of hope in this sector, allowing for a more eco-friendly alternative when performance factors are taken into account.

Tip: When selecting bearings for sustainable projects, consider the life cycle of the materials involved, including their manufacturing processes and end-of-life disposal options.

Tip: Always look for suppliers that prioritize eco-friendly practices, such as using recycled materials or adopting sustainable production methods, to minimize your overall environmental impact.

Related Posts

-

Unlocking the Details of Best Bearing Supplies with Key Technical Parameters for Global Buyers

-

5 Essential Tips for Choosing the Best Sealed Bearings

-

5 Key Factors to Choose the Best Stainless Steel Bearings for Global Procurement

-

7 Best Deep Groove Ball Bearings for Unmatched Performance

-

How to Efficiently Use the Best Ball Bearing Puller for Optimal Results

-

The Future of Ultra Slim Bearings for Innovative Applications