Top 10 Tips for Choosing Stainless Steel Ball Bearings for Your Projects

When embarking on a project that requires precise movement and low friction, the choice of components can significantly impact performance and longevity. Among these components, stainless steel ball bearings stand out as a reliable option due to their strength, corrosion resistance, and versatility. This introduction highlights the critical factors one should consider when selecting stainless steel ball bearings for various applications, whether in machinery, automotive, or industrial settings.

Understanding the unique properties of stainless steel ball bearings is essential for making informed choices. Their durability and ability to withstand harsh environments make them suitable for both heavy-duty operations and delicate systems. However, not all stainless steel ball bearings are created equal. Factors such as load capacity, size, and even the grade of stainless steel used can influence performance outcomes. In this guide, we will explore the top ten tips that will enable you to choose the right stainless steel ball bearings tailored to your project’s specific needs, ensuring optimal functionality and extended service life.

Choosing the Right Grade of Stainless Steel for Your Bearings

When selecting stainless steel ball bearings for your projects, choosing the right grade of stainless steel is paramount. Stainless steel grades vary in composition, corrosion resistance, and mechanical properties, which all influence the performance and longevity of the bearings in different environments. For example, grade 440C offers high hardness and wear resistance, making it an excellent choice for applications where durability is critical. On the other hand, grade 316 is known for its superior corrosion resistance, making it suitable for marine or chemical processing applications where exposure to harsh conditions is common.

Additionally, consider the specific requirements of your project when selecting a grade. If the bearings will be subjected to high temperatures or aggressive chemicals, opting for a higher-grade stainless steel might be necessary to prevent failure. It's important to assess the operating environment and load conditions to ensure that the chosen stainless steel grade aligns with the expected stresses and exposure, ultimately leading to improved performance and reduced maintenance needs in your applications.

Understanding Load Ratings and Their Importance in Application

When selecting stainless steel ball bearings for various applications, understanding load ratings is crucial. Load ratings, typically defined by dynamic and static capacities, indicate the maximum loads the bearings can support during operation. Dynamic load ratings refer to the bearing’s ability to handle loads under motion, while static load ratings pertain to the maximum load the bearing can endure when stationary. Knowing these ratings helps engineers and project managers ensure that the chosen bearings can handle the expected operational demands without prematurely failing.

In practical terms, choosing the right load rating involves considering factors such as the weight of the loads, operating speeds, and environmental conditions. For instance, high-speed applications may require bearings with higher dynamic load ratings to ensure smooth operation, while applications with heavy static loads might prioritize static ratings. Furthermore, environmental factors like temperature and exposure to contaminants can influence the effectiveness of bearings, necessitating a careful assessment of load ratings in conjunction with these conditions.

Being equipped with this knowledge enables professionals to make informed decisions, ultimately enhancing the reliability and longevity of their projects.

Evaluating Corrosion Resistance for Durability in Harsh Environments

When selecting stainless steel ball bearings for applications in harsh environments, evaluating corrosion resistance is paramount. Stainless steel is renowned for its ability to withstand corrosive elements, particularly when the material is treated to enhance its resistance. A report from the National Association of Manufacturers (NAM) indicates that corrosion costs U.S. industries nearly $276 billion annually, making the selection of durable materials essential for long-term operational efficiency. Choosing high-quality stainless steel bearings can significantly mitigate these costs, particularly in settings exposed to moisture, salt, or chemicals.

For optimal performance, it’s critical to consider the specific type of stainless steel used. Generally, 316 stainless steel is favored in marine and coastal applications due to its superior resistance to chlorides and corrosive environments. According to a study published in the Journal of Materials Science, bearings made from 316 stainless steel exhibit a 30% increase in corrosion resistance compared to their 304 counterparts when subjected to saline solutions. Furthermore, applying protective coatings or treatments can enhance durability, thus extending the lifespan of the bearings in demanding conditions. This comprehensive evaluation of corrosion resistance not only ensures reliability but significantly contributes to the reduced need for replacement, yielding cost savings over time.

Top 10 Tips for Choosing Stainless Steel Ball Bearings for Your Projects

| Tip | Description | Corrosion Resistance Rating | Typical Applications |

|---|---|---|---|

| 1. Material Selection | Choose the appropriate grade of stainless steel for your application. | AISI 304 - Moderate | Indoor equipment |

| 2. Load Capacity | Assess the dynamic and static load ratings to ensure durability. | AISI 316 - High | Marine applications |

| 3. Size and Dimensions | Verify the size of the bearings to fit your assembly. | AISI 440C - Very High | High-performance applications |

| 4. Lubrication | Select the right type of lubricant to enhance performance. | AISI 420 - Moderate | Food processing equipment |

| 5. Sealing Options | Consider sealed bearings for added protection against contaminants. | AISI 316L - High | Chemical processing |

| 6. Temperature Tolerance | Check the temperature range of the bearings for your environment. | AISI 304 - Moderate | General applications |

| 7. Environmental Factors | Evaluate exposure to harsh elements like salt, moisture, and chemicals. | AISI 316 - Very High | Offshore structures |

| 8. Noise and Vibration | Select bearings designed to minimize noise and vibration. | AISI 440C - High | Precision machines |

| 9. Cost-Effectiveness | Balance performance with budget to find the best value. | AISI 304 - Moderate | General mechanical applications |

| 10. Supplier Reputation | Source from established suppliers to ensure quality and reliability. | AISI 316L - High | High-reliability environments |

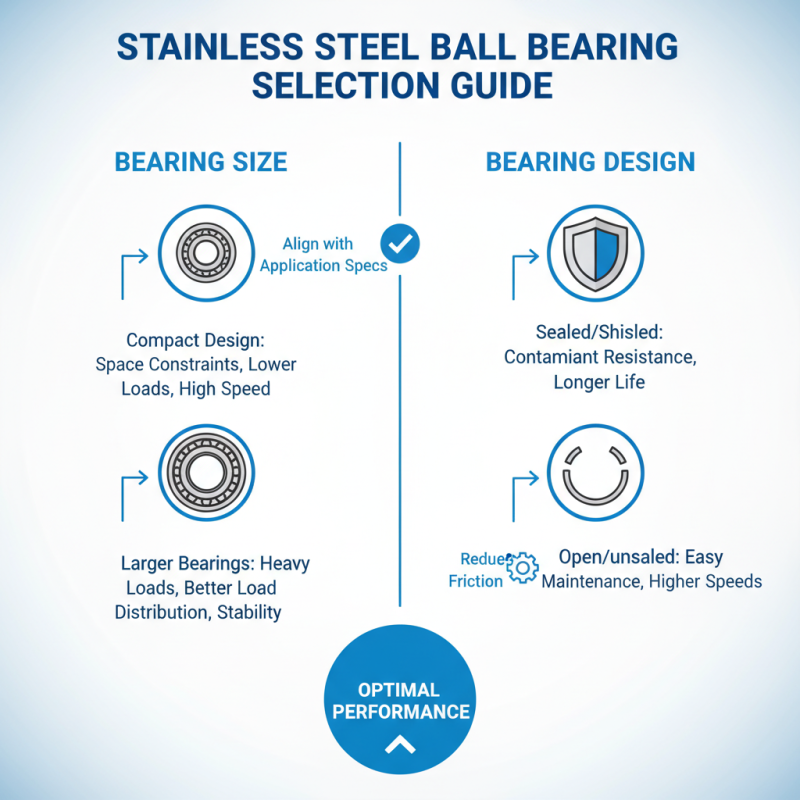

Assessing Bearing Size and Design for Optimal Performance

When selecting stainless steel ball bearings for your projects, assessing bearing size and design is crucial for achieving optimal performance. The size of the bearing must align with the specifications of the application, ensuring that it can handle the necessary load and reduce friction effectively. A compact design, in particular, is beneficial for projects with space constraints, while larger bearings can provide better load distribution for heavier applications.

One essential tip is to pay attention to the inner and outer diameters of the bearings. Selecting the correct size will not only enhance the efficiency of the machinery but also prolong the life of the bearings. Additionally, examining the design features such as raceway geometry can contribute to lower rolling resistance and better overall performance.

Another important aspect is to consider the type of sealing used in the ball bearings. Sealed or shielded options can significantly affect the longevity and maintenance requirements of the bearings. Choosing a design with appropriate seals can help keep contaminants out and lubricants in, thus minimizing wear and maximizing operational efficiency.

Identifying Trusted Manufacturers and Industry Certifications for Quality

When selecting stainless steel ball bearings for your projects, identifying trusted manufacturers and industry certifications is crucial to ensure the quality and reliability of your components. According to the latest data from the American Bearing Manufacturers Association (ABMA), only about 25% of manufacturers meet the rigorous standards required for high-quality bearings. This underscores the importance of scrutinizing manufacturers and seeking those with established reputations and relevant industry credentials.

Industry certifications such as ISO 9001 and ISO 14001 play a significant role in the evaluation of manufacturers. ISO 9001 focuses on quality management systems, ensuring that products meet customer and regulatory requirements consistently. Meanwhile, ISO 14001 reflects a commitment to environmental management, which is increasingly important in today’s industrial landscape. A report from the International Organization for Standardization (ISO) highlights that businesses with these certifications often demonstrate superior performance and lower defect rates, translating into enhanced product reliability.

Furthermore, engaging with manufacturers who are part of recognized industry organizations can provide additional assurance. For instance, adherence to guidelines set by the ABMA or equivalent bodies often signifies a commitment to best practices in design, manufacturing, and testing processes. By prioritizing manufacturers with these certifications and affiliations, engineers and project managers can mitigate risks and ensure that their stainless steel ball bearings will deliver optimal performance in demanding applications.

Top 10 Tips for Choosing Stainless Steel Ball Bearings

Related Posts

-

The Future of Ultra Slim Bearings for Innovative Applications

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

What Makes Ceramic Balls Essential for Modern Manufacturing

-

7 Reasons Why Deep Groove Ball Bearings are Essential for Your Business Success

-

Stainless Steel Ball Bearings vs. Plastic Bearings: A Comprehensive Performance Comparison

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair