Trust in Excellence: Discover the Best Thrust Bearings from China’s Leading Manufacturer

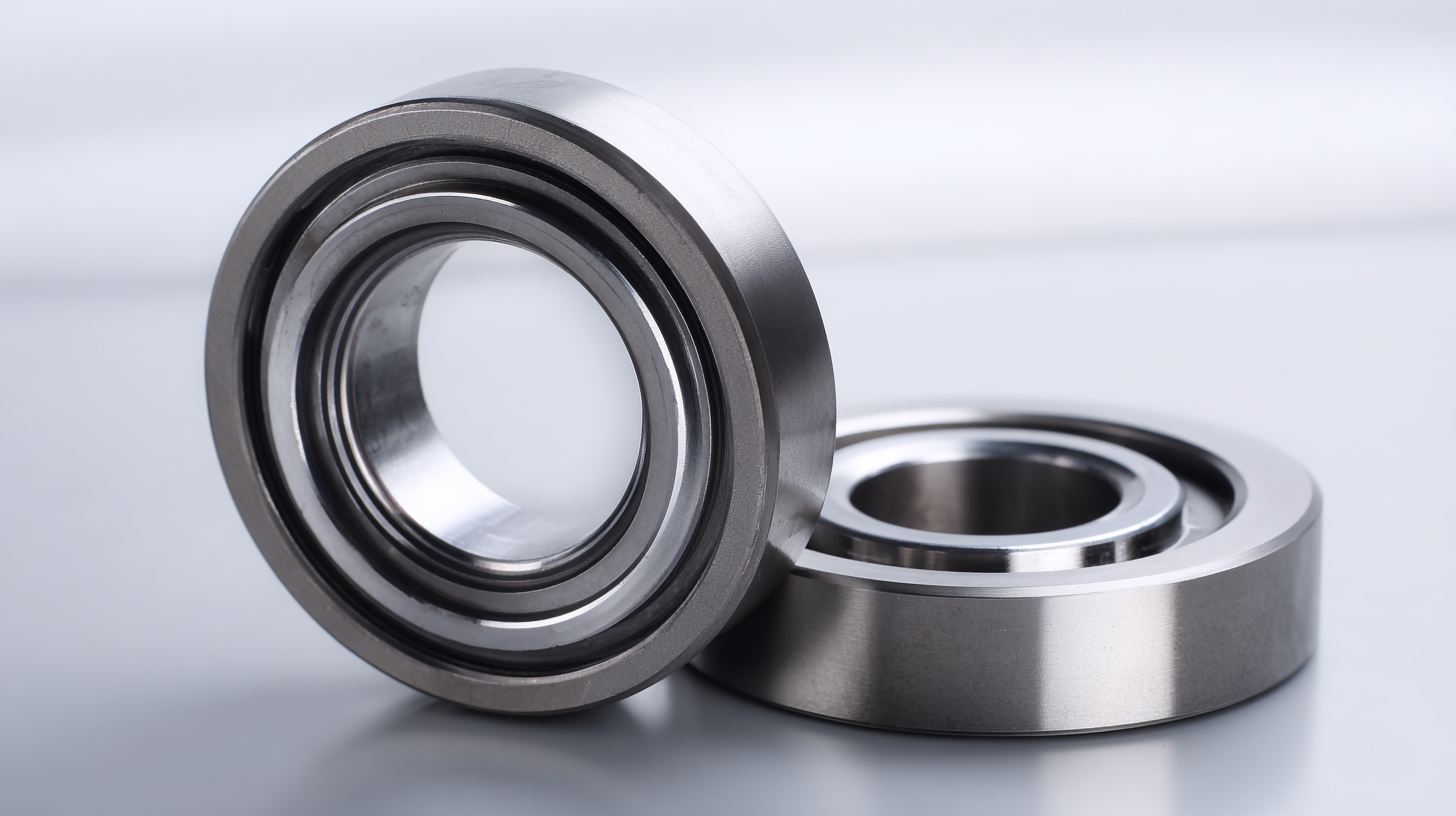

In the realm of mechanical engineering, the importance of thrust bearings cannot be overstated. These essential components play a critical role in managing axial loads in various applications, from automotive engines to industrial machinery. However, despite their significance, many users encounter a myriad of problems associated with thrust bearings, ranging from premature wear to improper alignment.

This blog delves into these common issues, shedding light on the challenges faced by engineers and maintenance professionals when dealing with thrust bearings. As we explore the intricacies of thrust bearing performance and durability, we will also highlight solutions provided by China’s leading manufacturers, known for their commitment to excellence and innovation.

Join us on this journey to uncover the best thrust bearings that not only meet but exceed industry standards, ensuring reliability and efficiency in all operations.

The Rise of Thrust Bearings: Key Trends to Watch in 2025

The demand for thrust bearings is set to surge as industries evolve and technological advancements redefine machinery requirements. By 2025, we expect to see a significant rise in applications across several sectors, including automotive, aerospace, and industrial machinery. This growth is driven by the increasing focus on efficiency and reliability, compelling manufacturers to innovate and enhance the performance of their products.

The integration of smart technologies and improved materials will play a pivotal role in shaping the thrust bearing landscape.

Moreover, sustainability is becoming a paramount concern, influencing manufacturing processes and product design. Leading manufacturers in China are prioritizing eco-friendly materials and production methods, aligning with global sustainability goals. This trend not only addresses environmental challenges but also appeals to consumers who are increasingly conscious of their choices. As they adapt to these changes, thrust bearings are expected to become more durable and efficient, meeting the high-performance standards required in modern applications.

Top Features That Define the Best Thrust Bearings from China

The global bearings market is experiencing significant growth, with its size projected to expand from USD 50.16 billion in 2025 to an impressive USD 97.10 billion in the coming years. Within this vibrant market, thrust bearings play a pivotal role, particularly with advancements being led by top manufacturers in China. The best thrust bearings are characterized by their superior design, materials, and performance attributes which include high load capacity, durability, and low friction coefficients. These features not only enhance the efficiency of machinery but also prolong the lifespan of other components in critical applications.

Among the various types of thrust bearings available, those that incorporate innovative designs, such as protuberant foil technology, demonstrate significant advantages under static loads. Scientific studies indicate that such designs minimize deflection, ensuring optimal contact under stress and contributing to improved reliability. As industries increasingly turn towards high-performance components to meet their operational demands, identifying and investing in the best thrust bearings from leading manufacturers becomes crucial for achieving operational excellence and maintaining competitive advantage in the marketplace.

Digital Innovations Transforming Thrust Bearing Manufacturing in 2025

As the manufacturing landscape evolves, digital innovations are set to transform thrust bearing production by 2025. According to a recent report by MarketsandMarkets, the global bearings market is projected to reach USD 100.93 billion by 2025, with the thrust bearing segment playing a significant role in this growth. Advanced technologies such as IoT, AI, and automation are expected to enhance efficiency in production processes and quality control, leading to higher performance levels in applications spanning automotive, aerospace, and industrial machinery.

Embracing these digital transformations, China’s leading thrust bearing manufacturers are investing heavily in smart manufacturing practices. A survey by Deloitte indicates that digital technologies could reduce operational costs by up to 20% in the manufacturing sector. This proactive approach not only streamlines operations but also minimizes human error, resulting in thrust bearings that meet rigorous industry standards. Furthermore, real-time data analytics will enable manufacturers to anticipate demand fluctuations and optimize inventory management, ensuring that they remain competitive in a rapidly changing global market.

Trust in Excellence: Thrust Bearing Manufacturing Advances in 2025

This bar chart illustrates the projected advancements in thrust bearing performance metrics by 2025, highlighting the top features prioritized by manufacturers.

Comparison of Leading Chinese Thrust Bearings: Quality, Performance, and Reliability

When it comes to thrust bearings, finding the right balance between quality, performance, and reliability is crucial for industrial operations. Leading Chinese manufacturers have set a benchmark in the global market, showcasing a range of thrust bearings tailored for various applications. By utilizing advanced materials and cutting-edge manufacturing processes, these manufacturers ensure that their products not only meet but often exceed international standards.

A close comparison of top thrust bearing brands reveals distinct advantages. Some manufacturers focus on durability and load capacity, making their bearings ideal for heavy machinery, while others emphasize precision engineering and low friction, catering to high-speed systems. User testimonials and industry reviews further highlight the performance of these products in real-world conditions, showcasing their resilience and efficiency. By choosing thrust bearings from reputable Chinese manufacturers, businesses can significantly enhance operational reliability and overall performance.

How to Choose the Right Thrust Bearings for Your Industry Needs in 2025

When selecting the right thrust bearings for your industry needs in 2025, it's essential to consider the specific requirements of your application. Thrust bearings are critical components that support axial loads in machinery, thus ensuring optimal performance and longevity. As the global bearings market is projected to grow significantly, understanding the technical specifications and materials available will aid in making informed decisions.

Tip 1: Focus on the load capacity and speed ratings of the thrust bearings. Ensure the bearings you choose can handle the expected loads and speeds without compromising performance. Always refer to manufacturer data sheets for detailed specifications.

Tip 2: Material composition is crucial for durability and resistance to wear. For heavy industrial applications, consider bearings made from high-strength steel or specialized materials designed to resist extreme conditions.

Tip 3: Look for manufacturers that provide comprehensive fault detection solutions, such as those utilizing advanced technologies like wavelet transforms for early detection of faults. This can significantly reduce downtime and maintenance costs by identifying potential issues before they escalate.