The Ultimate Guide to Ball Transfer Units in 2025 Exploring Top Choices

In 2025, the realm of logistics and material handling continues to evolve, with ball transfer units (BTUs) playing a crucial role in enhancing operational efficiency. As industries strive for streamlined processes and reduced lead times, insights from leading experts underscore the importance of these innovative devices. According to a recent report by the Global Material Handling Industry Association (GMHIA), the market for ball transfer units is expected to grow by over 15% annually, driven by the increasing demand for automation in warehouses and distribution centers.

Expert in material handling technologies, Dr. Emily Carter, emphasizes the significance of ball transfer units in modern logistics. "Ball transfer units not only facilitate smoother movement of goods but also significantly reduce the risk of damage during transit," she notes. These units allow for multidirectional movement, making them essential for layouts where space optimization is critical. As businesses adapt to ever-changing market needs, the strategic implementation of ball transfer units highlights their integral role in maintaining competitive advantage.

As we delve deeper into the top choices for ball transfer units in 2025, it is vital to consider factors such as load capacity, durability, and maintenance requirements. This guide aims to equip industry professionals with the knowledge necessary to make informed decisions that will enhance their operational capabilities and respond effectively to the growing demands of the material handling sector.

Understanding Ball Transfer Units: Definition and Functionality

Ball transfer units (BTUs) are versatile, low-friction devices that facilitate the movement of heavy objects in various applications, from warehouses to assembly lines. These units consist of a series of ball bearings housed within a frame, allowing objects to glide effortlessly in multiple directions. The primary function of a ball transfer unit is to enable smooth, omnidirectional handling of goods, enhancing efficiency in logistics and manufacturing processes. Their design minimizes surface contact, reducing wear and tear while providing seamless movement.

Understanding the functionality of ball transfer units is crucial for industries that rely on the transportation of materials. When a load is placed on the unit, the balls rotate freely, allowing the load to shift in any direction without significant resistance. This capability is particularly beneficial in tight spaces where maneuverability is essential. Additionally, many BTUs are designed to withstand heavy loads and harsh conditions, ensuring durability and longevity in demanding environments. Their ability to simplify material handling processes makes them an invaluable component in enhancing operational efficiency across various sectors.

Key Components of Ball Transfer Units: What You Need to Know

Ball transfer units (BTUs) are crucial components in material handling systems, known for facilitating the easy movement of heavy items in various industrial settings. Understanding the key components of BTUs is essential for making informed decisions about their application and maintenance. The primary elements include the ball bearings, housing, and loading plate. The ball bearings, typically made from high-strength materials, are strategically placed within the housing to provide a smooth surface for items to glide over. Industry reports indicate that the demand for ball transfer units is projected to grow by approximately 6% annually, driven by advancements in automation and increasing efficiency needs across sectors.

The housing structure of a ball transfer unit can significantly influence its performance. Different designs, such as those featuring reinforced materials, can enhance durability and load capacity. According to a recent market analysis, over 40% of maintenance issues in automated systems stem from inadequate components, highlighting the importance of selecting BTUs with robust housing designs. Furthermore, the loading plate should be well-matched to the expected weight and type of products it will support, as this directly impacts the operational efficiency and longevity of the unit. Adopting best practices in the selection of BTUs will not only optimize material handling processes but also reduce overall downtime and maintenance costs, making them a critical investment for modern industrial environments.

Top Features to Consider When Choosing Ball Transfer Units for 2025

When selecting ball transfer units for 2025, several key features should be prioritized to ensure optimal performance and reliability. First and foremost, the load capacity of the units is crucial; choosing a unit that can handle the weight of the items being transported will prevent wear and tear and potential breakdowns. Additionally, examining the materials used in the construction of the ball transfer units can also impact their durability and suitability for various environments. For instance, options made from corrosion-resistant materials can enhance the longevity of the units, especially in industries where exposure to moisture or harsh chemicals is common.

Another important consideration is the ball transfer unit’s rotational movement capabilities. Units that allow for multidirectional movement can significantly improve the efficiency of handling operations in warehouses and manufacturing environments. This flexibility can enable smoother transitions and reduce the likelihood of backtracking or collisions when moving items in tight spaces. Furthermore, assessing the ease of installation and maintenance of the units can save time and resources, making it vital to choose designs that simplify these processes without compromising functionality. By focusing on these essential features, businesses can ensure that their investment in ball transfer units meets their operational needs in the evolving landscape of 2025.

The Ultimate Guide to Ball Transfer Units in 2025

| Model | Load Capacity (kg) | Ball Diameter (mm) | Material | Operating Temperature (°C) | Certifications |

|---|---|---|---|---|---|

| Model A | 150 | 25 | Steel | -20 to 80 | ISO 9001 |

| Model B | 200 | 30 | Plastic | -10 to 70 | CE |

| Model C | 250 | 35 | Aluminum | -30 to 90 | RoHS |

| Model D | 100 | 20 | PVC | -15 to 60 | ANSI |

| Model E | 180 | 28 | Stainless Steel | -25 to 85 | ISO 14001 |

Leading Brands and Models of Ball Transfer Units in the Market Today

Ball transfer units (BTUs) have become essential components in various industries, providing seamless movement of heavy loads across flat surfaces. As we delve into 2025, several leading brands have made significant strides in enhancing the design and functionality of these units. These innovations focus on durability, load capacity, and ease of maintenance, ensuring they meet the demands of modern material handling systems.

In today’s market, the top choices of ball transfer units vary in design, size, and operational capabilities. Manufacturers are prioritizing the incorporation of advanced materials that reduce friction and enhance performance, allowing for smoother transitions and improved longevity. Additionally, many models are designed to be adaptable, catering to specific applications, such as assembly lines, logistics, and warehouse operations. By evaluating the features of these models, businesses can select BTUs that align with their operational needs, ultimately leading to greater efficiency and productivity in their workflow processes.

Future Trends in Ball Transfer Unit Technology and Applications

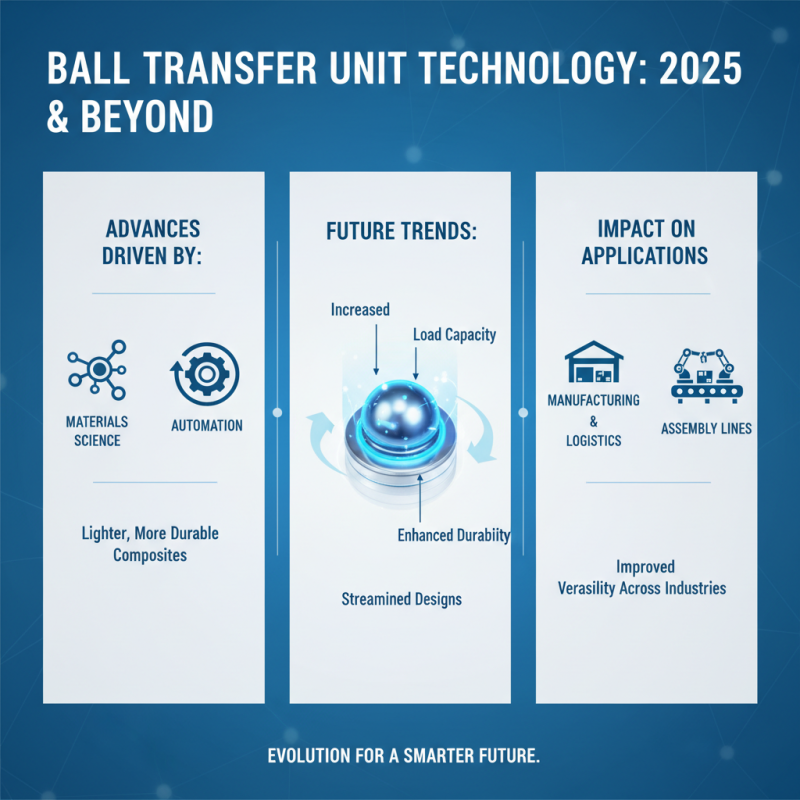

As we move into 2025, the landscape of ball transfer unit technology is poised for significant evolution, driven by advances in materials science and automation. Future trends indicate a shift toward lighter, more durable composites that can withstand increasing loads without sacrificing performance. This evolution not only enhances the efficiency of manufacturing processes but also allows for more streamlined designs in various applications, from warehouses to assembly lines.

Moreover, the integration of smart technology within ball transfer units is set to transform their functionality. With the rise of IoT (Internet of Things), these systems will have the capability to communicate real-time data on load distribution, wear and tear, and operational status. This connectivity will enable predictive maintenance, minimizing downtime and optimizing supply chain operations. As industries look for ways to improve productivity and reduce costs, the adoption of advanced ball transfer unit technology will likely play a critical role in achieving these objectives, marking a noteworthy trend in the industry’s future direction.

Related Posts

-

How to Choose the Right Ball Bearing Rollers for Your Application Needs

-

Exploring the Future of Ball Bearing Rollers Industry at the 2025 China Import and Export Fair

-

Top 10 Tips for Choosing Stainless Steel Ball Bearings for Your Projects

-

Exploring the Future of Stainless Steel Bearings: Innovations and Applications in Modern Engineering

-

Understanding the Basics of Ball Bearing Selection for Optimal Performance

-

The Future of Engineering: Exploring the Innovations in Thin Section Bearings Technology